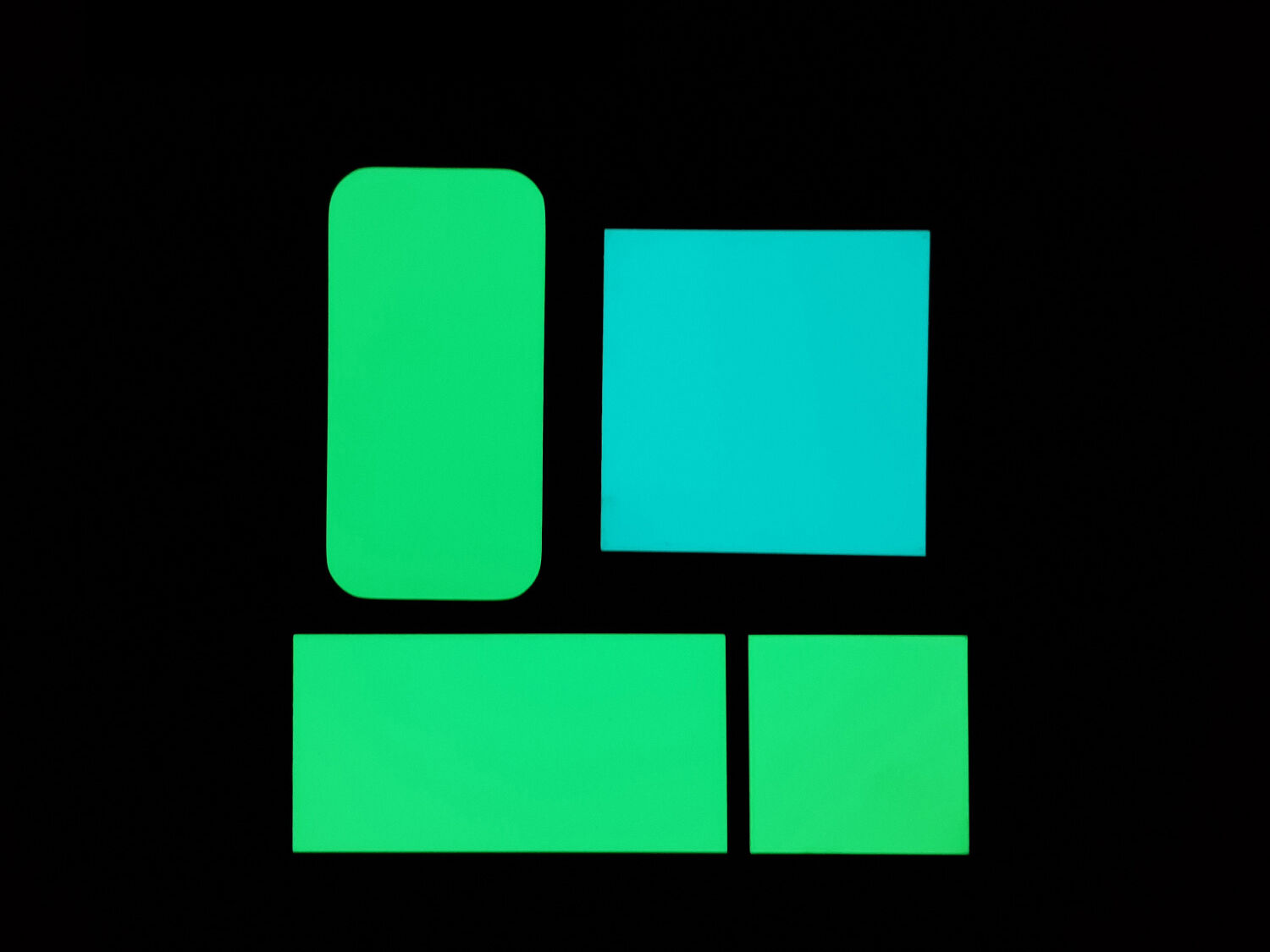

The luminescent board containing no radioactive elements is non-toxic and harmless, it absorbs light efficiently, has a long afterglow and long service life.

There are two types of luminescent boards based on different processes: composite luminescent boards (made by mixing luminescent powder with several types of PVC resin under specific conditions) and ordinary luminescent boards (with a luminescent film on a PVC base sheet).

Main performance:

1.It has a certain flame-retardant performance.

2.It has a certain resistance to salt water and detergent (can be washed with detergent).

3.It has excellent resistance and cold resistance, which can be used in environments from -20 to 60℃.

4.It has relatively good physical and mechanical properties.

Instructions:

1.It should be processed on a smooth surface, and the operational temperature should be between 10 and 40℃.

2.The surface can be printed with patterns or text to form a low-profile light-emitting effect.

3.For the same type of PVC luminescent board, there might be color differences among batches to ensure brightness.

Processing notes:

1.The back shade can be adhered with glue according to customers’ requirements.

2.It can be cut into different sizes (thickness from 0.8 to 1.6mm) as required.

3.There are multiple brightness levels.

4.The surface can be subjected to processes such as color spraying and printing.

5.It is with good flame-retardant performance and widely applied in various fire safety signs, warning signs, and marine signs.

Products Recommended